How To Design Figures For 3d Printer

Miniatures are small scale replicas or models of something else. Sometimes these are toys, props, demonstrational pieces, or collectibles. Due to their tiny size and precise details, minis may be complicated to handcraft, especially in a larger quantity. 3D printing, on the other hand, provides a way to manufacture miniatures with decent quality and production time. But in order to make it work for your needs, there are a few facts to consider in regards to 3D printing small figurines and minis.

- 3D Printing Technologies comparison

- Materials Rundown

- Post-Processing for printed Minis

- Quick design tips for each Printing tech

- Why should I choose to 3D print miniatures?

- How to order 3D printing of miniatures

Different types of miniatures

There are several areas, where small scale replicas and models are used, each sphere with its intricacies respectively. Here is a quick rundown of the small size figurines we are touching upon:

- Tabletop wargaming minis

- Action figures

- Model figures

- Scale models

- Diorama pieces

- Landscape models

- Rail transport models

- Dollhouse props

- Educational models

Though all miniatures have much in common, they differ not only in size but also in the functionality of pieces as well as accuracy and stiffness requirements. As a result, certain production methods and 3D printing materials will suit each type of piece better.

What 3D printing methods are there for minis

Miniatures and figurines can potentially be 3D printed using any available method. However, depending on the application and requirements, some techs are more suitable than others.

| Technology | Material type | Affordable | Detail Quality | Stiffness | Color |

| FDM/FFF | Plastic | 5/5 | 2/5 | 4/5 | Usually monochrome |

| [Resin] SLA | Resin | 3/5 | 5/5 | 3.5/5 | Monochrome |

| [Resin] DLP | Resin | 3/5 | 4.5/5 | 3.5/5 | Monochrome |

| [Resin] DUP | Resin | 4/5 | 4/5 | 3.5/5 | Monochrome |

| [Resin] MJ/Polyjet | Resin | 2/5 | 5/5 | 4/5 | Full-Color |

| SLS | Nylon Powder | 3/5 | 4/5 | 4/5 | Monochrome |

| CJP | Sandstone | 2/5 | 3/5 | 2/5 | Full-Color |

FDM/FFF

One of the most affordable methods works by heating up plastic strings and using it to form a piece layer by layer. The big downside of the technology is that it leaves some layer lines as well as marks under overhanging parts. In order to print minis with FDM, it is usually required to have a separate, thinner nozzle, and slower printing time to ensure better details. Fused deposition modeling, though, can work fine for bigger scale models, some educational models, and rail transport models of larger size.

Figurine 3D printed on FDM machine by OKSharPei 3D

VAT polymerization/Resin printing

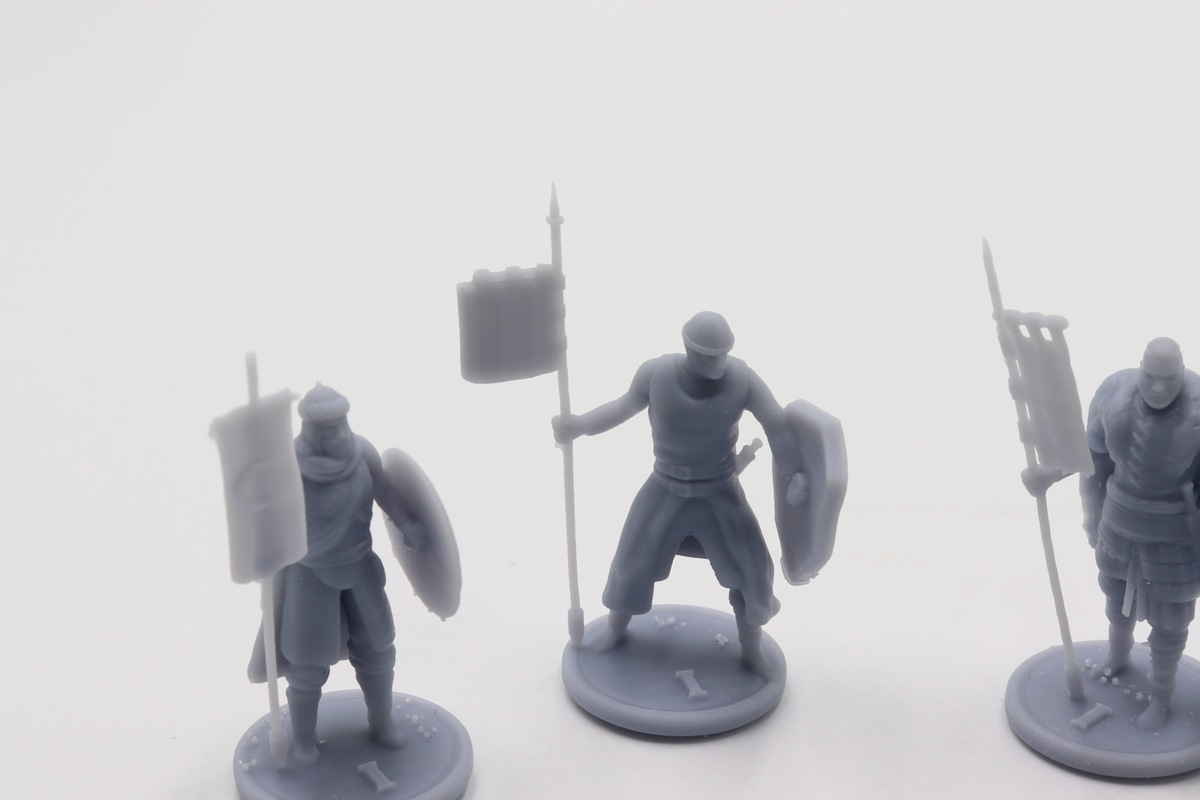

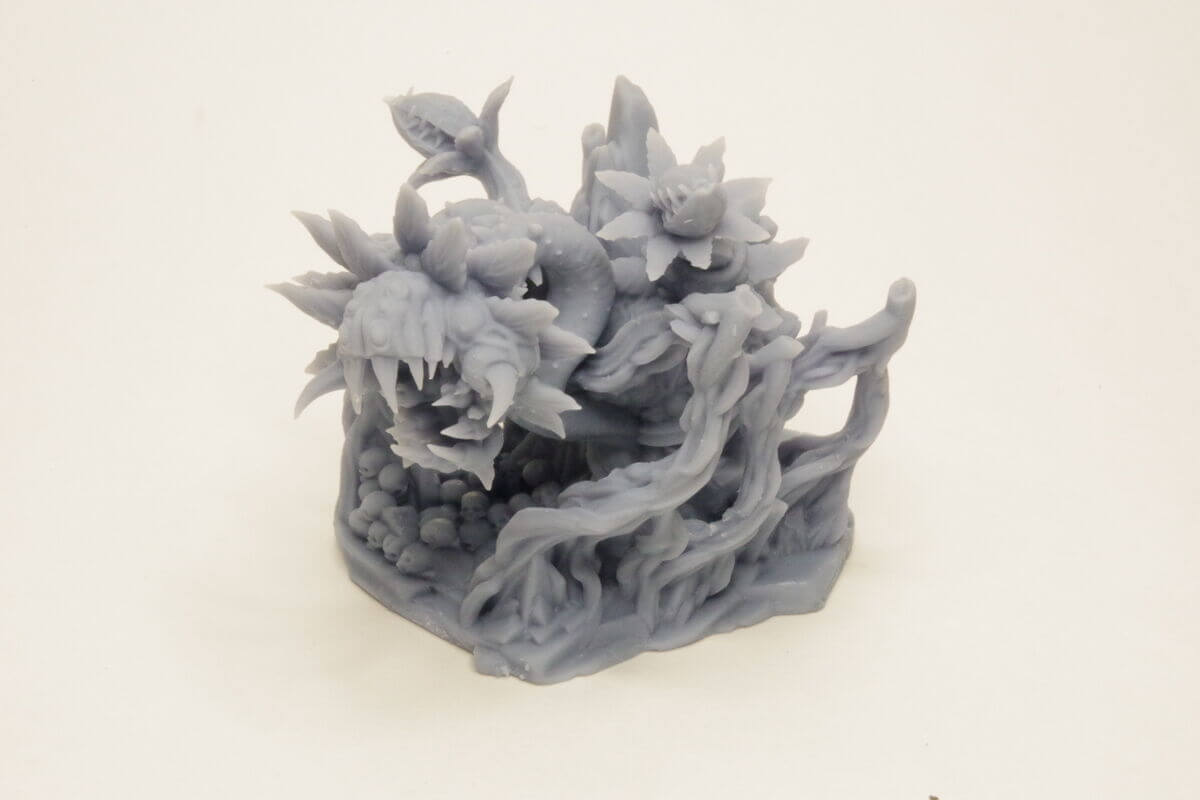

Resin 3D printing is a family of technologies that cures liquid photopolymers layer by layer by laser, LEDs, or projectors. These methods suit miniatures really well as they allow preserving intricate details while keeping a smooth surface. However, you should take into consideration that some resins or technologies suit it better. For example, laser-based machines commonly help avoid voxelization of a piece. And for high-detailed minis, special HD resins are recommended. Overall, SLA miniatures are suggested for tabletop wargaming that doesn't require functioning parts.

3D print by Brandon's 3D Printing

MJ/Polyjet

This set of 3D printing technologies works with UV-activated resins. But contrary to vat polymerization methods, it works with droplets of resins, which allows mixing them to get different colors and properties. These advantages make MJ a good method for educational and demonstration models.

3D print by AllgaeuTec

Laser Sintering

Powder sintering is usually a professional manufacturing method that relies on sintering nylon-based powders. It is capable of making sturdy and accurate minis free of layer lines. Aside from costly production, laser sintering has some limits to its precision, but overall allows a great quality of figurines. If preceding through sintering, it is a good idea to order a small batch rather than a single piece to save some money as nesting (printing a batch) is usually more cost-efficient. This method should suit action figurines, props, and landscape models.

3D printed chess set from a personal portfolio of Rapid 3D Parts

Color Jet Printing

CJP technology uses sandstone powder and a binding agent that fuses grains together layer by layer. In the process, inks add color to a part. Through combining several primary colors, these machines commonly deliver a wide range of shades. End results are full-colored, they have a medium quality of details. Compared to other methods, CJP provides more brittle minis. Consider choosing Color Jet Printing for colored landscape models, model figurines that won't be actively used or memorabilia pieces.

3D print by Make it 3D Manufacturing Center

What Materials to choose for Miniatures

Within each 3D printing technology, there are always several material options. Choosing a suitable one for your mini makes or breaks the results.

FDM Plastic

PLA is one of the most common and user-friendly plastics out there. There are many interesting options available as well as colors. It is one of the best filaments in terms of details, and medium choice in regards to stiffness and temperature resistance. With right post-processing and coating, PLA will be serving you decently.

Other FDM options include ABS, PETG, Wood-filled plastics, and many more. However, these are usually the types of plastic printed with higher temperatures, which raises chances of failures and artifacts such as echoing and warping.

Generic resin

All-purpose resin is a standard photopolymer used. It is easy to find, and it produces fine results in terms of detailing. It is a bit brittle in thinner areas and prone to warping in unsupported small overhangs.

High-detail resins

With a bit different formulation, these resins allow getting more details to come out. Even when a machine's resolution allows it to go to 25-50 microns precision, other resins may not support that tolerance. HD resins, on the other hand, are designed to allow 3D printing such fine elements.

SLS Nylon

PA 12 is a pretty standard material used in Laser sintering. It combines good detail transition and technical parameters. Other grades of nylon are okay to use for minis, too. Such materials are pa 6, pa 6/69, and more. For miniature printing, composites or flexibles would be a bad choice, so sticking to usual polyamide is the best you can do.

Sandstone

Sandstone is one of the primary materials used in CJP along with powders like gypsum or nylons.

Polyjet polymers

MJ processes use UV-activated polymers close to the resins in SLA and DLP printers. However, these machines are able to combine and blend together different grades of their own polymers to get complex results. Some common materials include Rigid opaque resins and Clear ones, Vero, Agilus, Tango, and more. They can either provide a glossy-looking smooth surface finish or matte texture.

A Quick look on Post-Processing of 3D Printed Figurines

All 3D printed miniatures require post-processing and finishing touches, though some may need less work than others. Key steps for all printed figurines are likely to include:

- Supports removal

- Sanding

- Smoothing or Polishing

- Sealing

For 3D printing processes except for powder-based ones (SLS, CJP), a miniature will probably require cleaning the surface from supporting structures. This process is usually easy but requires accuracy and patience when it comes to small pieces. The main goal is to ensure intricate details will not be damaged. Many 3D printing services offer support removal but can charge an additional fee for smaller models or large quantities since it is a time-consuming task.

Supporting structures can be removed at home as well without much special skills or tools required.

Check out Custom 3D printable Miniature models:

How to Design models suitable for 3D printing

Another step to getting a good-looking miniature is to ensure you have a proper 3D design. Certain metrics and clearance must be included in a model with technology in mind. Thus, it is a good idea to settle on a printing method before making or optimizing a file. Here are some general tolerance guidelines for the mentioned technologies.

FDM

- Try to reduce the number of overhangs and angles less than 45 degrees;

- Model design details to be larger than 1.15 mm or at least 0.5 mm;

- Ensure a model's wall thickness of 1.2 mm at least;

- For text, prefer thicker fonts and opt for 1 mm depth/height for it.

Resin Printing

- Model figurines hollow if you want to reduce cost;

- Include escape holes to the design to avoid uncured resin inside your piece;

- If possible, keep the detail size greater than 0.05mm.

SLS and CJP

- Hollow enclosed parts are not possible, thus, include holes or model parts solid;

- Recommended detail size is bigger than 0.8 mm;

- Suggested wall thickness is around 0.7 mm - 2.0 mm;

- For text details, ensure depth/height about 2 mm.

For beginners, it can be a good idea to use someone's designs that were tested for 3D printing before. Or, as an option, you can hire a designer to either create a custom model or rework the one you have on hand to suit the process.

Why should I choose to 3D print miniatures?

3D printing is a good method of getting custom parts in low quantities. With a ready 3D model, turnaround times for printing figurines are also quite short. FDM and DUP printing methods are usually affordable as well. More precise methods have a competitive advantage of accuracy when it comes to thin details and allow to create smaller figurines.

3D printing will not be able to fully replace outstanding handmade miniatures, however, it can serve as a fine alternative or a base for painting and customizing.

Additionally, when several similar models are required, a 3D printed master model will come in handy for casting purposes.

3D print by 3D Printer Filaments

How to order 3D printing of miniatures?

There are 2 main options you can use to order 3D printing of miniatures through Treatstock:

- Instant Order

- Getting a Quote

If you already have a printable 3D miniature and know for sure what material suits your application, then instant order will probably be the easiest way for you. Upload your model, choose specifications, and fill in delivery details to get the cost estimation and order 3D prints:

For more complicated models or projects without optimized 3D models, we recommend using the "Get a Quote" option. A quote allows contacting a print service before setting up on a price and specifications. That way you can get help with choosing proper settings and technology to achieve the goals or order additional services like post-processing, painting, and coating.

To search for vendors that offer 3D printing, visit the catalog. This way also helps to find a specific technology like SLA printing service or Material Jetting.

You can also check out design on-demand offers to have a starting point and apply for a 3D model first or find a suitable miniature in our store.

How To Design Figures For 3d Printer

Source: https://www.treatstock.com/guide/article/194-introduction-to-3d-printing-custom-miniatures

Posted by: coxouthad.blogspot.com

0 Response to "How To Design Figures For 3d Printer"

Post a Comment